An Unbiased View of Premier Aluminum Llc

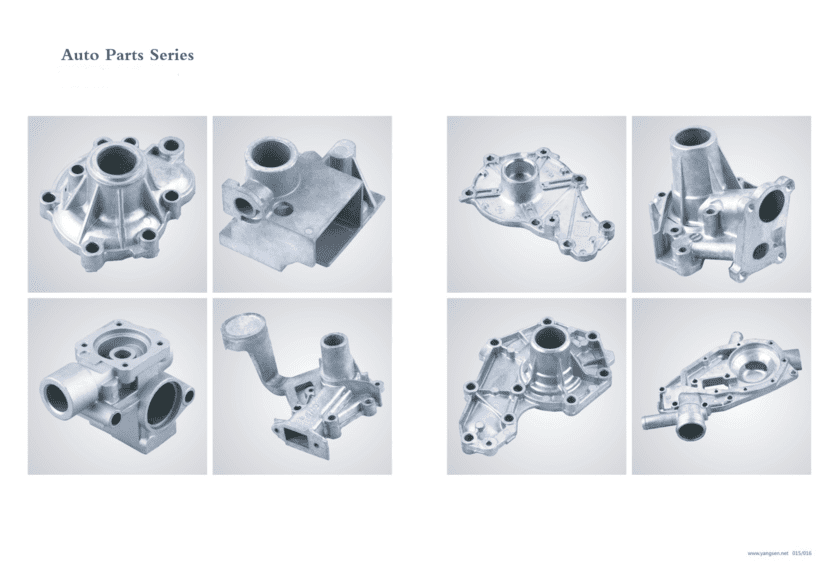

Once the sand is made, the liquid light weight aluminum is poured right into it and allowed to chill. Aluminum spreadings have residential properties nearly like various other light weight aluminum components. Once the casting procedure is full the light weight aluminum castings promptly develop an exterior layer of alumina that helps shield against corrosion. Aluminum casting processes are explained as Ingot casting or Mould spreading.

The 2nd procedure is utilized within the shops for creating cast products. Foundry near me. This is frequently the oldest and most basic (in concept yet not in practice) means of creating shaped components. This area defines exclusively Mould spreading which might be split right into 2 primary groups: Other strategies like "lost foam" or "wax pattern" processes also are utilized yet their cost-effective importance is considerably less than both provided techniques

The preparation and for that reason the bonding of this sand mold are the vital step and actually typically are the rate-controlling step of this procedure. Two major routes are made use of for bonding the sand molds: The "eco-friendly sand" includes mixes of sand, clay, and dampness. The "dry sand" includes sand and man-made binders treated thermally or chemically.

Top Guidelines Of Premier Aluminum Llc

Mold developing may be a specifically complicated art and is based on a comparable principle as gravity pass away casting detailed in Number 4. In the "low pressure" sand spreading method, the thawed steel is compelled to go into the mold by reduced difference. This a lot more challenging process allows the setting up of actors items with thinner wall density.

High passes away casting is that the most normally utilized, representing concerning 50% of all light alloy casting production. Gravity passes away casting accounts for the remainder, with the exception of a little however the growing payment from the just recently introduced vacuum cleaner dies spreading and squeeze casting process.

A lot of components comprising a timeless mold for gravity pass away spreading. Cores (internal components of the mold) are usually made from adhered sand. Gravity dies casting is suitable for production and for fully mechanized light weight aluminum casting. In this light weight aluminum casting procedure, the fluid steel is injected at broadband and high into a steel mold and mildew with the assistance of die spreading equipment.

Getting The Premier Aluminum Llc To Work

One plate is fixed and therefore the various other can move in order that the die is typically opened up and shut. A determined quantity of steel is put right into the shot sleeve then introduced into the mold dental caries utilizing a hydraulically driven piston. When the steel has strengthened, the die is opened and consequently the spreading is eliminated.

The pressure inside the die is decreased by an air pump and consequently the distinction of stress requires the liquid metal to get in the die. This transfer is a smaller quantity turbulent than other spreading strategies in order that gas inclusions are typically very limited. Consequently, this new strategy is specifically intended toward elements that will subsequently be heat-treated.

The dies are after that closed. During the best phases of closure, the liquid is displaced into the more components of the die. helpful hints No excellent fluidity requirements are demanded of the fluid because the displacements are small. Hence building alloys, which normally have inadequate fluidities which typically avert the spreading route, are commonly cast by this process.

What Does Premier Aluminum Llc Do?

Squeeze spreading pressures liquid aluminum to infiltrate the preformed as compared to non-reinforced light weight aluminum alloy, light weight aluminum alloy matrix composites manufactured by this system can increase the tiredness stamina at 300C. Such supports are typically utilized at the sides of the piston head of a diesel where solicitations are particularly high.

This write-up covers the primary usual elements that add to a choice on which approach is the appropriate one for you. Along a side a quick review of every variable, we'll keep in mind which of the three procedures fulfills that require ideal: Sand Casting automated procedures, like at Dolin Spreading Manufacturing, gives a high outcome of components during a brief quantity of your time in contrast to permanent mold and mildew procedures.

9 Easy Facts About Premier Aluminum Llc Explained

Comments on “Not known Facts About Premier Aluminum Llc”